Our challenges involve dealing with problems that don’t have a ‘correct’ answer. Mr. Kato, a member of the Advanced Business Promotion Department, focuses on developing technologies that will support the Tajima Group moving forward.

As a student, Mr. Kato was interested in two subjects: machinery and materials. He then chose to work at a company where he could utilize his expertise: TISM. From the way he says, “I feel like I’m growing every day,” it’s clear that he’s doing an excellent job as a developer. Here he talks about the rewarding nature of his work in pursuing unknown technology.

The Possibilities of Conductive Thread

When he was a student researching carbon fiber reinforced plastic (CFRP), his laboratory used a Tajima embroidery machine. His interest in the machinery was what ultimately prompted him to decide on his career path. Sensing the potential and depth of embroidery machines, he joined TISM.

After joining the company, Mr. Kato was assigned to the Advanced Business Promotion Department. Here, the team develops cutting-edge technologies that lead to the creation of new businesses. One project the department worked on, called the “Smart Textile Business,” focused on manufacturing using conductive thread—thread that conducts electricity—which is an advanced material. Explains Mr. Kato, “One example of the use of conductive threads is wearables, a subject that has recently attracted considerable attention. For example, a material is being considered for wearable products that can detect a person’s physical status, such as blood pressure and heart rate.” The company is currently prototyping samples and developing proposals for products using conductive thread.

The Ability to Understand Customers’ Issues

Another project that Mr. Kato is involved in is Tajima’s TFP Business. This deals with products using “tailored fiber placement” (TFP), a process in which reinforcing fibers are sewn onto a base material to create a preform (intermediate base material). Describing the method’s features, Mr. Kato says, “Compared with traditional methods that use sheet materials such as textiles, TFP results in less wasted material. Additionally, when the customer asks to have greater strength in a particular direction, we can precisely orient the carbon fibers a certain way to increase the strength.”

Although Mr. Kato is highly focused on the use of TFP in prototyping, his role is not limited to that alone. Compiling the results of prototyping in documents and communicating the information to customers is crucial as well. This first requires repeatedly communicating with the customers and understanding the issues they face.

Continuous Effort to Obtain the Latest Information.

“If you can identify the customer’s issues, you can then see what suggestions are needed to resolve them,” says Mr. Kato. Once he understands an issue, he promptly comes up with a solution and suggests it to the customer. Seeing the resulting happiness of the customer is what motivates him in his work. “There are times when a customer who trusts me asks, “Is it possible to do something like such-and-such?’ That’s when I get fired up and think, “Yeah, let’s implement that idea next.”

Mr. Kato knows that we need to gather information on a daily basis in order to continue meeting our customers’ expectations. In particular, he actively participates in academic conferences and research groups with the aim of learning about cutting-edge technologies. Meanwhile, the search to create new core businesses for TISM continues to accelerate.

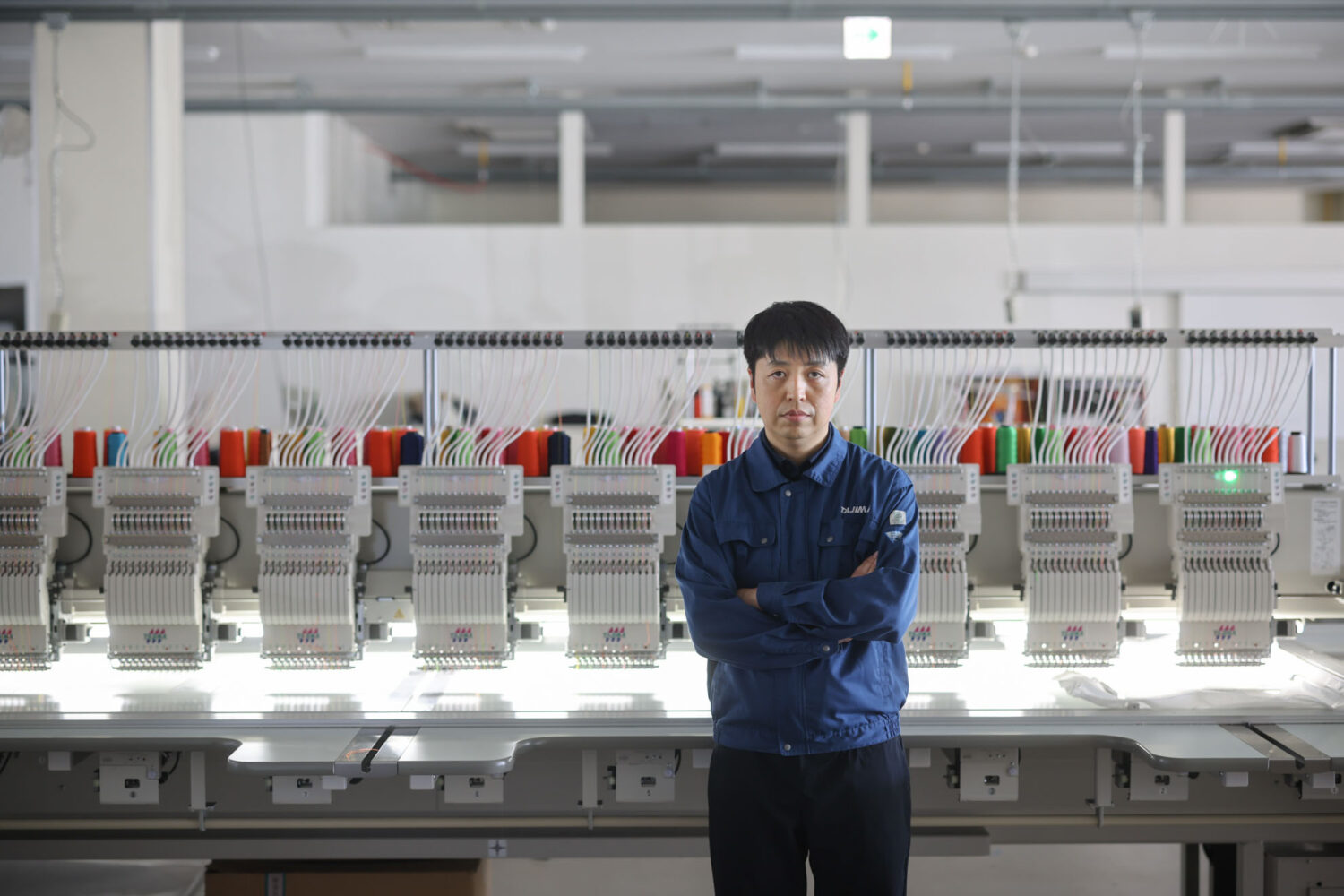

Sales & Planning Division | Daiki Kato

Born in 1997

Joined in 2020

As a university student, he used a Tajima embroidery machine in his graduation research.

That experience led him to join the company.

He continues to hone his technical and communication skills while developing cutting-edge technologies at the Advanced Business Promotion Department.