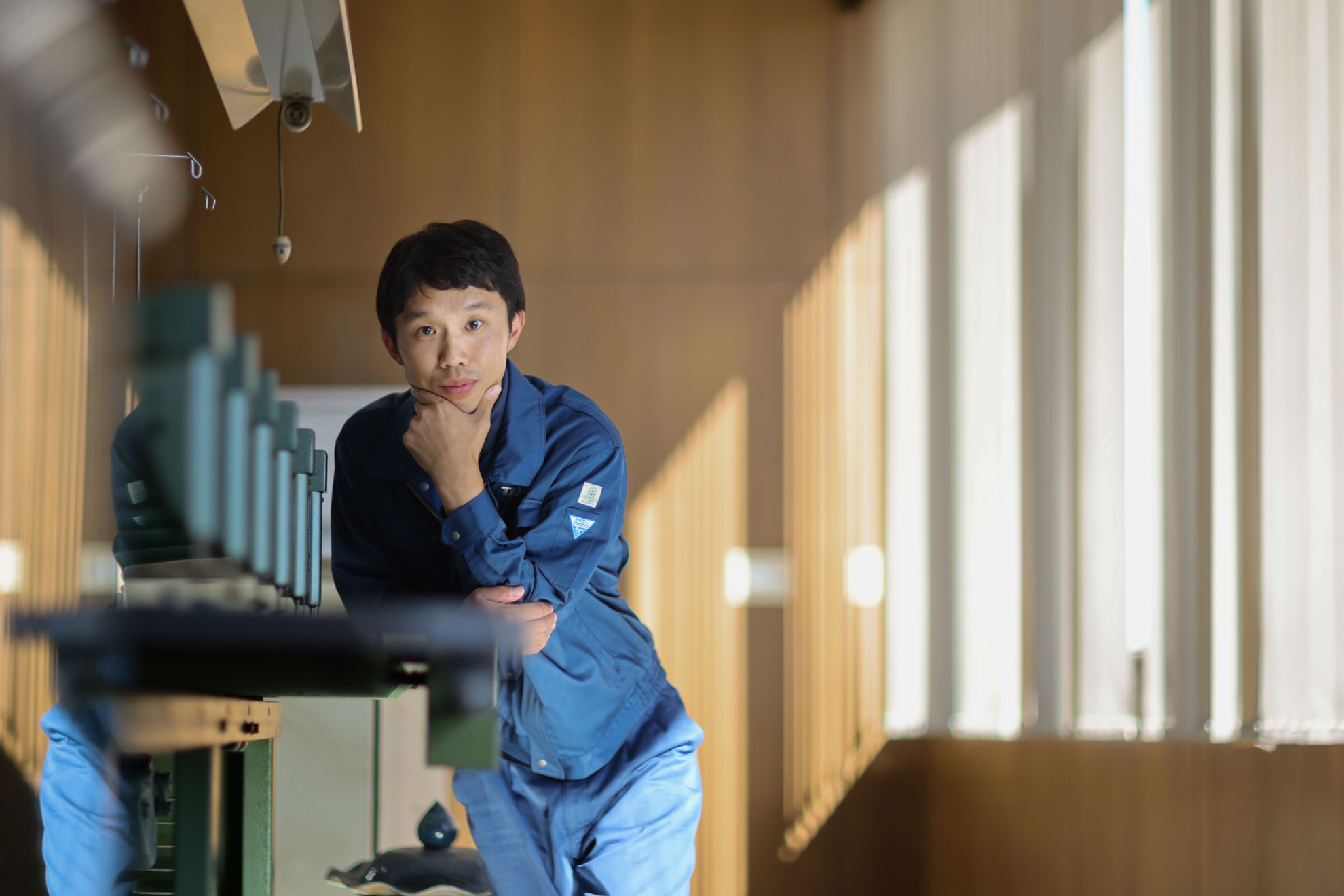

When Mr. Yoshida talks about manufacturing, his tone is calm, yet occasionally, it carries a passionate undertone. He was involved in the development of the compact “Tajima SAI” embroidery machine as a mechanical designer. Later, he came to be active in various areas of product development and technical research. What kind of challenges has he faced when creating a new product? And what kind of joy awaits beyond that? Mr. Yoshida looks back on the path he has taken.

At First, Just Trying to Keep Up

Mr. Yoshida planned to work for a manufacturing company, but he really wanted to work for a company that manufactured its own products. Mr. Yoshida conducted his job search with this thought in mind. He decided to join TISM based on the appeal of the representative from Tajima in charge of explaining the company at a job fair.

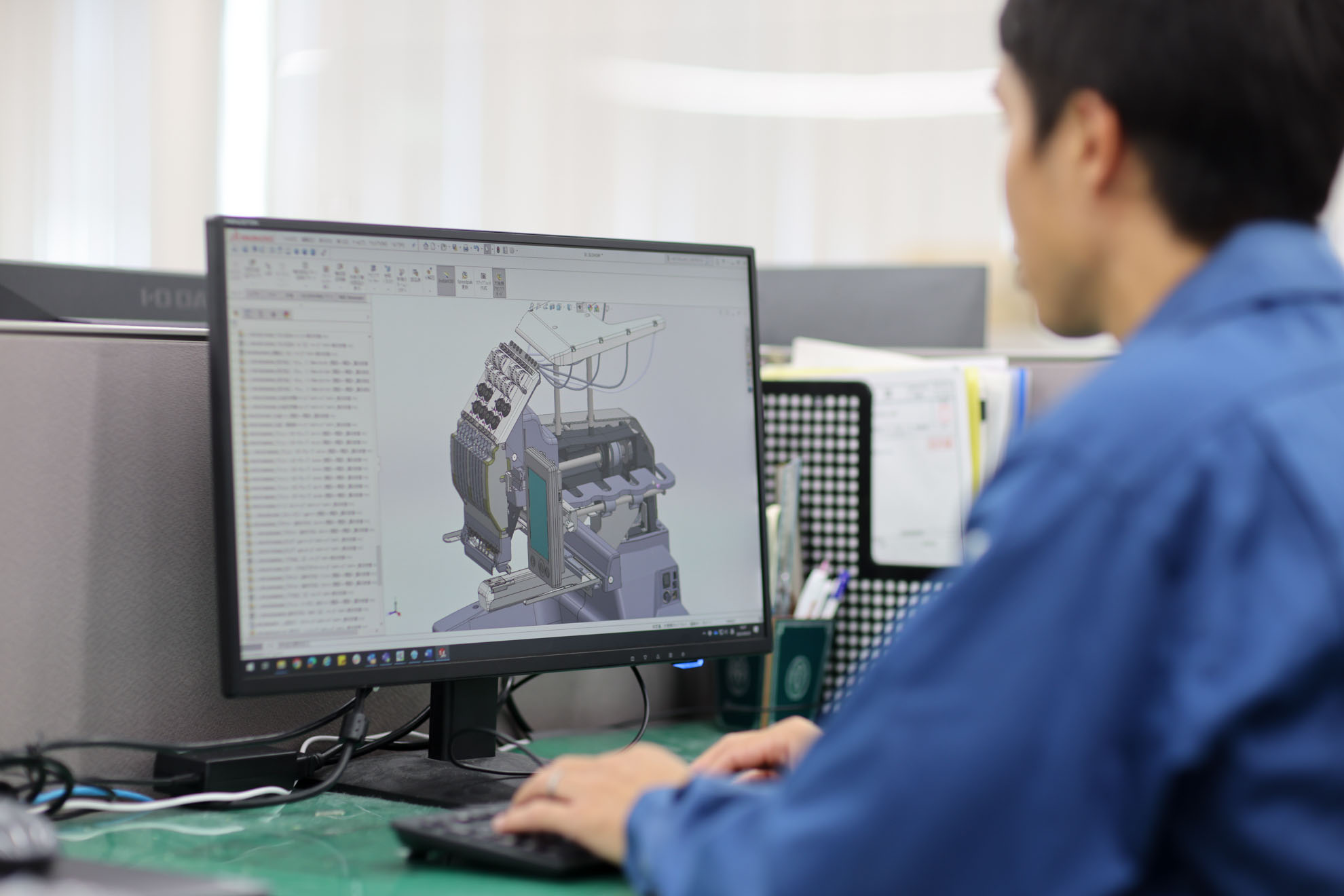

“Until my second or third year here, I was just trying to keep up,” says Mr. Yoshida. After joining the company, he honed his skills, working on product improvement until his mid-20s. In his late 20s, he was involved in new product design and research into sewing techniques. One project that left a particularly strong impression on him was when he was in charge of mechanical design during development of the Tajima SAI. With a highly anticipated lead-up, this new product is much more compact than conventional embroidery machines and designed to be more beginner-friendly. However, development of this project did not progress as initially expected.

Succeeding Because of the Team

One of the difficulties that Mr. Yoshida and his team faced during the process of developing the SAI was changing the specifications one year before product’s release.

He recalls, ‘I still remember how some of the specifications were changed, even after the first lot was completed. If it weren’t for the team we had at that time, I don’t think we could have responded within such a short period.

On the other hand, the development of SAI involved many firsts for TISM, including the first time the company collaborated with external designers and first OEM contract (original equipment manufacturer, commissioned by other manufacturers). Mr. Yoshida visited the contracting manufacturer numerous times and held discussions repeatedly to resolve the issues that came up. These interactions were a fresh, new experience for Mr. Yoshida and his colleagues. Such is how this new product, incorporating the designer’s many ideas, came to be completed.

Developing the Next Generation of Human Resources

Several years have passed since the SAI development project, and Mr. Yoshida is now involved in manufacturing in a different capacity than before. He explains, “I was concentrating on design at the time, but now my subordinates handle that role. My current responsibility is to support designers other than myself.” If he gets another opportunity to develop a new product like SAI in the future, he would like to utilize his skills in a different position than before.

With his evolving role, Mr. Yoshida is now dedicating considerable effort to developing the human resources who will play a key role in TISM in the future. Anticipating the growth of his team, the scope of manufacturing involving his engagement is set to expand. With this expectation in mind, he is actively training the upcoming batch of engineers.

Development Division | Takahiro Yoshida

Born in 1986

Joined TISM in 2009

After being in charge of product improvement and other duties, he is now engaged in mechanical development for new products and research into sewing technologies.

He had primary responsibility for mechanical design during the development of “Tajima SAI.”

In his days off, he enjoys spending time with his two children.

This article is based on information available as of April 19, 2023.