Beautifully embroider on leather and thick materials.

The Digitally Controlled Presser foot (DCP) applies proper pressure based on fabric thickness changes in just 0.05 seconds per stitch.

It makes embroidery on tough materials like leather and thick fabrics easy and neat. It also reduces fabric flutter, which helps prevent skipped stitches for a smooth and beautiful finish.

- Achieve a precise and beautiful finish by minimizing fluttering, which can lead to inconsistencies and errors in embroidery.

- Easily and beautifully finish 3D embroidery and embroidery on difficult materials such as leather and thick materials.

Special features of the “DCP”

With conventional embroidery machines, the presser foot rises from the fabric simultaneously with the needle, lifting the fabric as the needle is removed and causes the fabric to “flutter,” which causes inconsistencies in the embroidery.

DCP automatically sets the presser foot at the optimal height based on the thickness of the fabric and runs independent of the needle, which helps minimize fluttering.

Effective examples for DCP

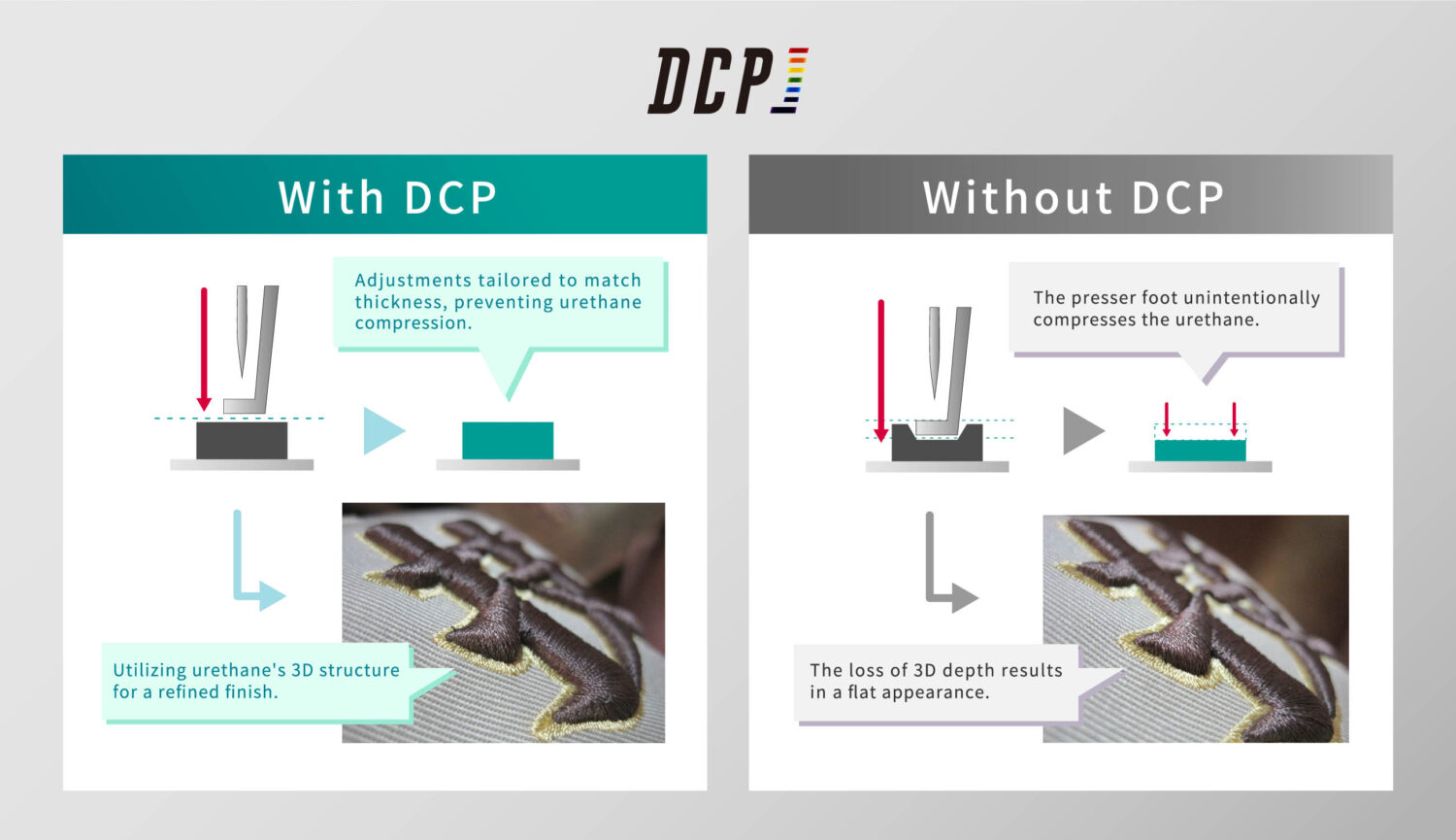

3D embroidery

An embroidery machine with DCP can automatically apply proper pressure based on the thickness of the fabric, providing a beautiful finish, even with changes in the thickness.

Accelerate your business further by combining with “i-TM”

Adjusting thread tension, which requires professional skills, can be done automatically with an embroidery machine equipped with the i-TM. Even beginners of embroidery can reproduce the skills of master craftsmen and achieve even more beautiful results.

Products Featuring “DCP”

-

Embroidery machine|Single-head Cylinder Type

TMBR2-SC

Single-head cylinder type high-end model enables stable embroidery processing on finished products

- High-end

-

-

Embroidery machine|Multi-head Cylinder Type

TMAR-KC

Multi-head Cylinder Type High-end Model (2-8 heads) enables stable embroidery processing on finished products

- High-end

-

-

Embroidery machine|Multi-head Flat Type

TMCR-VF

Multi-head Flat Type high-end model can enable stable mass production

- High-end

-

Products Featuring “i-TM + DCP”

-

Embroidery machine|Single-head Cylinder Type

TMEZ-SC

Single-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery machine|Multi-head Cylinder Type

TMEZ-KC

Multi-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery machine|Multi-head Flat Type

TMCR-VF+i-TM

Multi-head Flat Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

TAJIMAG

Recommended content

-

Dialogue・Special feature

Tabio Co., Ltd. | Creating new value through embroidery. Producing one-of-a-kind socks, unique in all the world.

-

Customer’s voice

Tabio Nara Co., Ltd. | Introduction of the DG.NET embroidery solution creates new ways to enjoy embroidery!

-

Customer’s voice

Kutsushitaya Kichijoji store|Embroidery Services Fulfilling Customers’ Wishes Custom embroidery socks in just 30 minutes!