SERVICES

HISTORY

CHANGE

01

DISTRIBUTOR TO MANUFACTURER

Industrial embroidery machine developed

1944

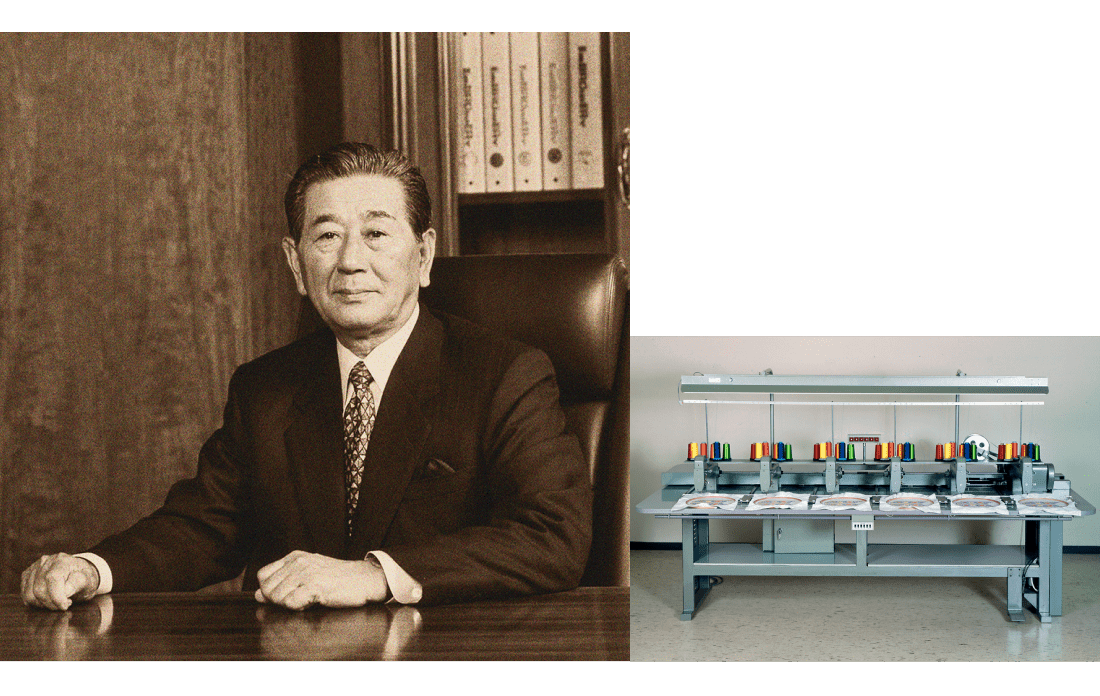

Established Tokai Industrial Sewing Machine Limited Private Company

The founder, Ryo Tajima, established an industrial sewing machine sales company in Aichi, laying the foundation for the current Tajima Group.

Later, after the end of the war, the fashion industry came back to life with the reconstruction of Japan.

1964

Started the manufacture and sales of Multi-head Automatic Embroidery Machines.

Ikuo Tajima, the second generation, developed a multi-head automatic embroidery machine over a period of four years and turned the company into a manufacturer.

With a single-minded desire to solve the problems of customers, he pushed forward with technological development on a daily basis. This is where Tajima's history as an embroidery machine manufacturer began.

CHANGE

02

FROM A LOCAL COMPANY TO

A GLOBAL COMPANY

The unprecedented golf boom made one-point logos popular!

TAJIMA's multi-color embroidery machine becomes a worldwide hit!

1970

Developed the world's first "jump mechanism" for embroidery machines.

Establishment of Tajima Industries Ltd.

Japanese designers such as "Issey Miyake" and "Kenzo" are active around the world and have released many innovative collections.

While the Japanese fashion industry was attracting attention on the international stage, Tajima developed the "Jump Mechanism" to improve embroidery production efficiency.

In the same year, Tajima established Tajima Kogyo K.K. to further strengthen its sales division and established a sales structure to bring Tajima's embroidery machines to markets around the world.

1972

Trade name changed from "Tokai Industries Sewing Machine Co., Ltd." to "Tokai Industrial Sewing Machine Co., Ltd."

1978

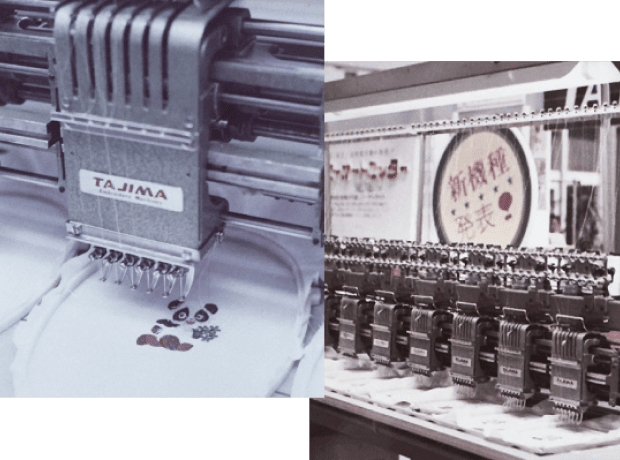

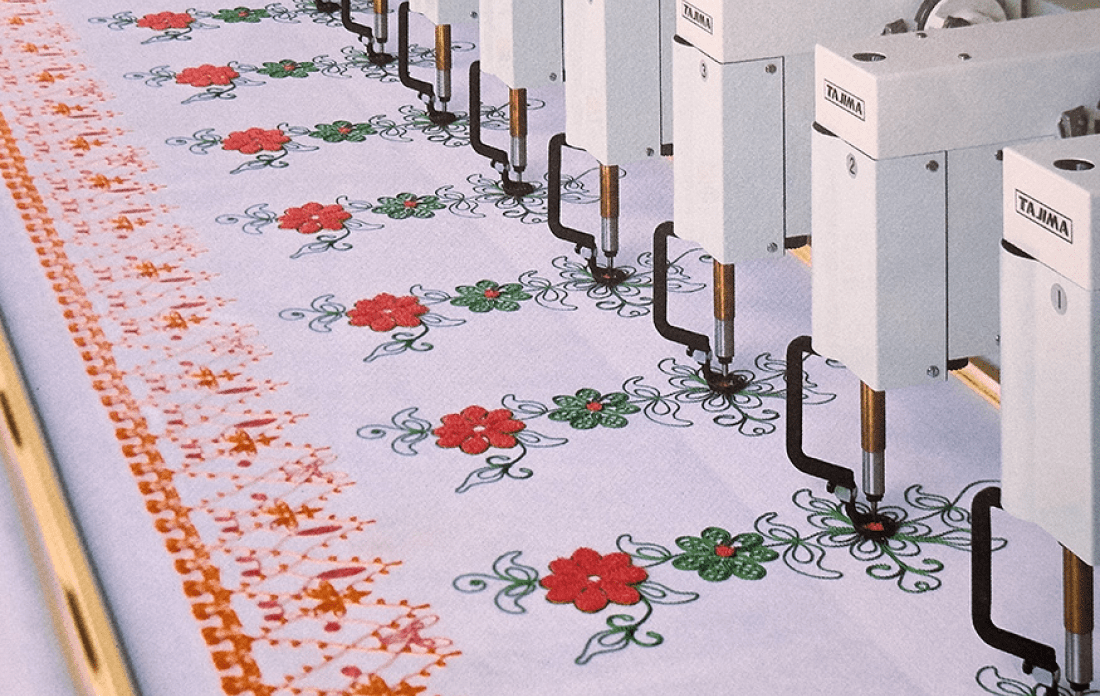

Released "6-needle (6-color) automatic thread change type electronic embroidery machine".

Combined with the unprecedented golf boom, one-point logos became all the rage.

In response to the growing need for colorful embroidery, Tajima introduced an embroidery machine with an automatic thread change function.

This function reduced the time and effort required to change threads for multi-color embroidery and improved productivity for multi-color embroidery.

1982

Released the world's first "Multi-head Electronic Chenille Embroidery Machines”

The process by which craftsmen used to produce each item one by one with a ring-stitching machine called a "hand handle" has been automated for the first time in the world.

The range of machine embroidery expression has been dramatically expanded to include soft and warm moss stitch embroidery and chain stitch embroidery with knitted patterns.

1986

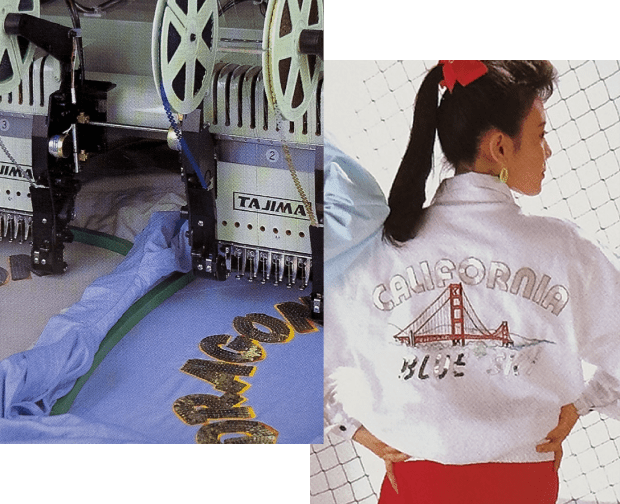

Released the world's first "Sequin Embroidery Machines”

The unique glitter of sequins became widely popular as a new means of fashion expression.

Tajima developed an embroidery machine that could combine sequin and flat embroidery.

The combination of sequin's glamour and flat embroidery's traditional beauty opened up a wide range of design possibilities.

1990

Establishment of “Tajima America Corporation” in the United States.

1997

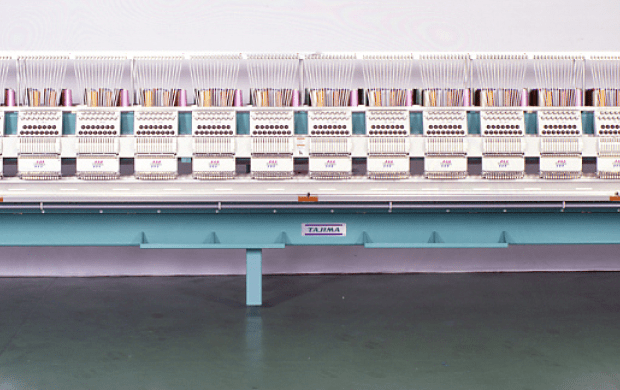

Released "15-needle electronic embroidery machine”

This year marked a turning point in the history of fashion, when many of the greatest creations in the history of fashion were created.

The 15-needle (15-color) embroidery machine, which has now become the mainstream, was completed, and decorative embroidery with richer colors took root in the fashion industry.

CHANGE

03

FROM DECORATIVE EMBROIDERY MACHINES

TO DECORATIVE AND FUNCTIONAL

EMBROIDERY MACHINES

New entry into non-apparel business utilizing embroidery technology

2004

Establishment of “Shanghai Tajima Embroidery Machinery Co., Ltd.”in Shanghai, China.

2008

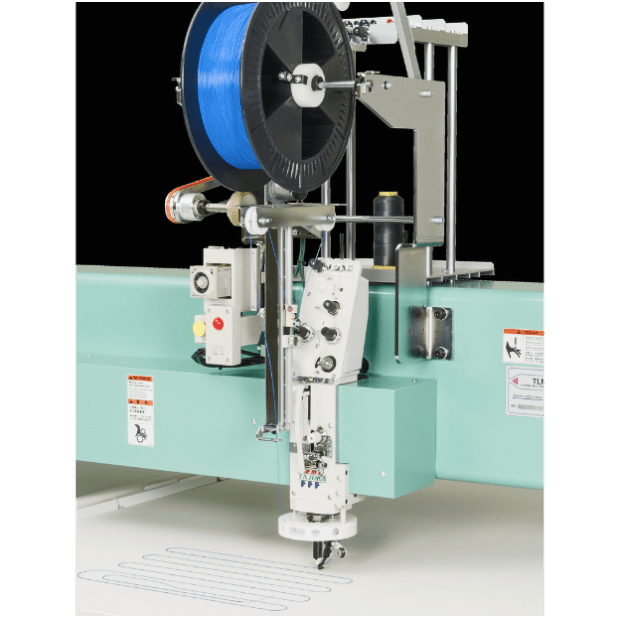

Released "TLMX" heater wire sewing machine

Developed a machine for sewing heater wires by applying the mechanism of cord embroidery.

The machine can be used for sewing heater wires on car seats, steering wheels, electric blankets, hot carpets, and many other items.

Embroidery technology is now widely used outside the apparel industry.

2009

Released "TCWM", a specialized composite fiber sewing machine

We developed a machine for preforms by sewing together reinforcing fibers such as carbon fibers.

Compared to conventional methods, the anisotropy of reinforcing fibers (strength is generated only in the fiber orientation) can be maximized, resulting in both lightweight and high rigidity.

It has been introduced in various fields such as the aerospace and automotive industries.

2011

Established “Tajima Europe S.A.R.L.” in the France.

2014

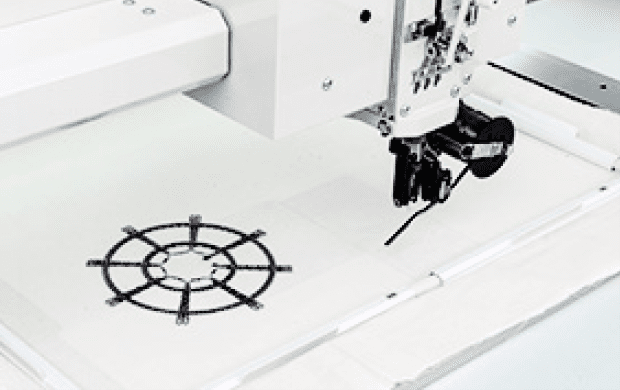

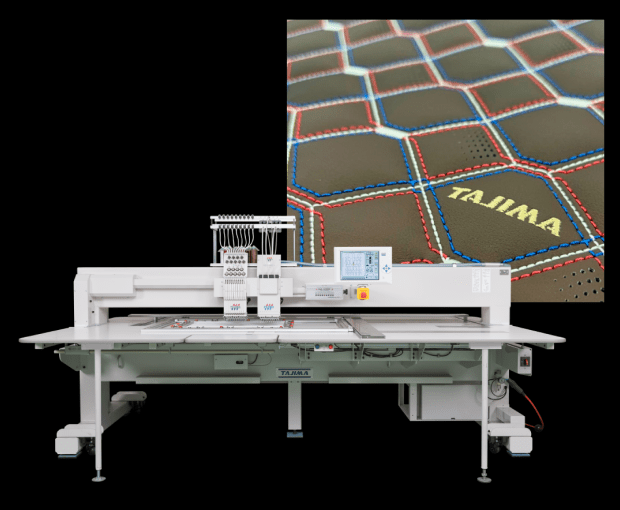

Released "PAX" multi-color & perforation automatic sewing machine

Applying and developing embroidery technology (sewing and frame control technology), "PAX" was developed to perform hole processing, multi-color sewing, and multi-color embroidery on a single machine.

By integrating data creation and machine usage, which used to be done for each process, into a single machine, even elaborate designs can now be beautifully processed.

PAX is used in a variety of industries, including car seats and interior decorating.

2017

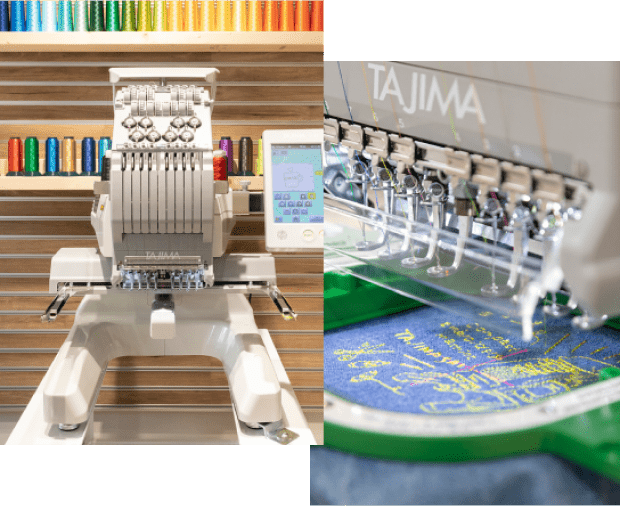

Released "SAI" the compact embroidery machine

In an effort to broaden the scope of embroidery, the compact embroidery machine "SAI" is marketed to general consumers.

The compact size has been achieved while maintaining the performance required by professionals, such as the beauty of the finished product and speed.

The machine is small and easy to use, and is also used for embroidery services at stores and other facilities.

2019

Company name changed from "Tokai Industrial Sewing Machine Co., Ltd." to "TISM Co., Ltd."

Released AI embroidery machine "TMEZ”

AI-based automation supports the shortage of manpower (skilled operators), which has been a major issue at production sites.

By automatically adjusting the upper thread, which greatly affects the finished embroidery, the system achieves high-quality results without the need for complicated adjustments.

This contributes to labor shortages, homogenization, and productivity improvement at factories.

CHANGE

04

FROM SELLING PRODUCTS

TO PROVIDING SOLUTIONS

Aiming to be the "World's Best Embroidery Company”

2022

Established “Tajima Software Solutions Inc.” in Canada.

We have welcomed a Canadian software company into our group in order to realize more advanced product development, sales, and after-sales service in terms of both hardware and software.

As the embroidery industry's first comprehensive solutions company, we will strive to further improve our services to our customers.

TAJIMA CONTINUES

INTO THE FUTURE