Improving your Living Space with Embroidery

Home is where we are the most every day.

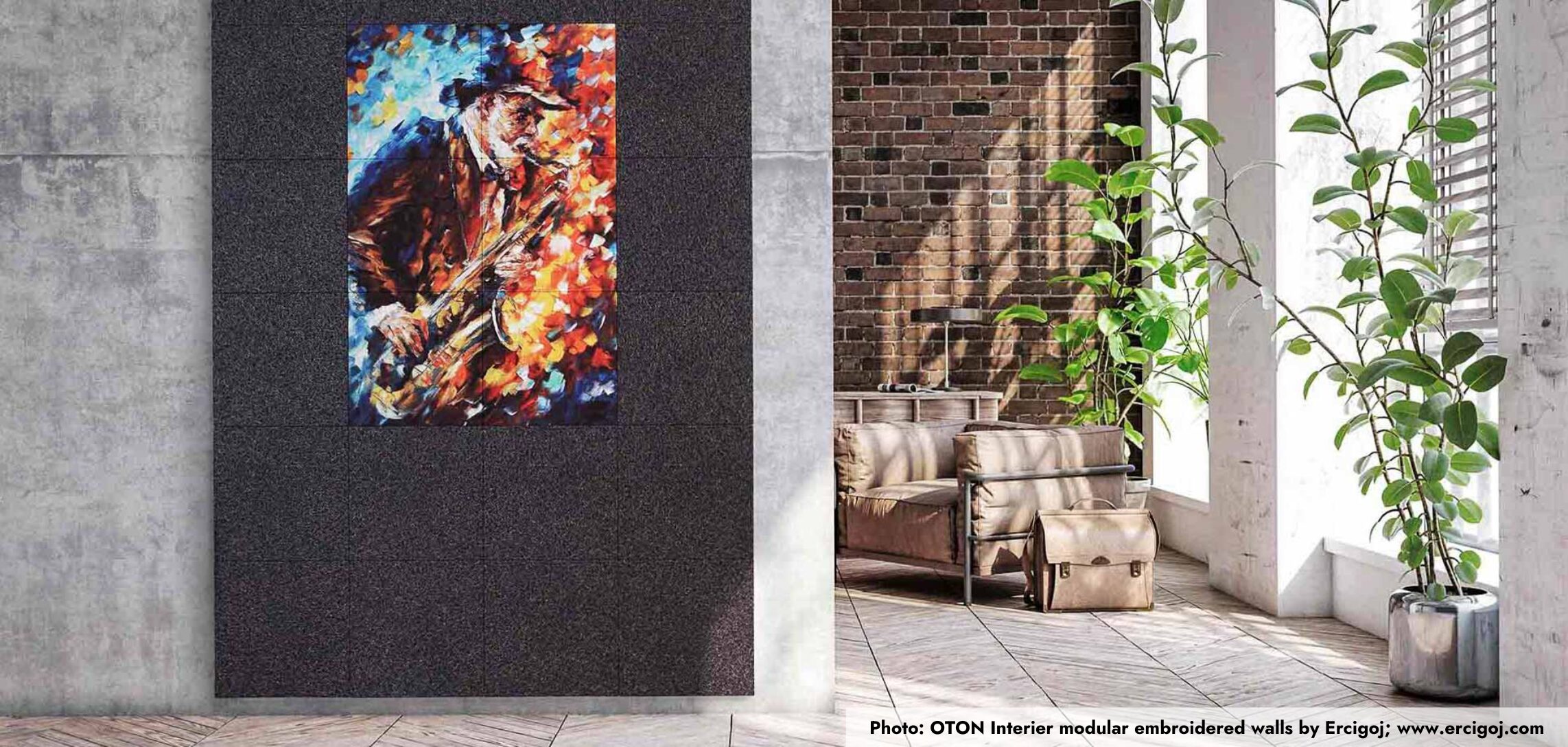

With the diversification of lifestyles, the “home” is not just a space for eating and sleeping, but has become a place that plays a variety of roles, including work, hobbies, and communication with family and partners, and the demand for more comfortable spaces is increasing. By using Tajima’s embroidery technology and cutting-edge technology, we can add various added values in terms of functionality as well as visual decoration.

Perforation, multicolor sewing, and multicolor embroidery

unites in creating function and art

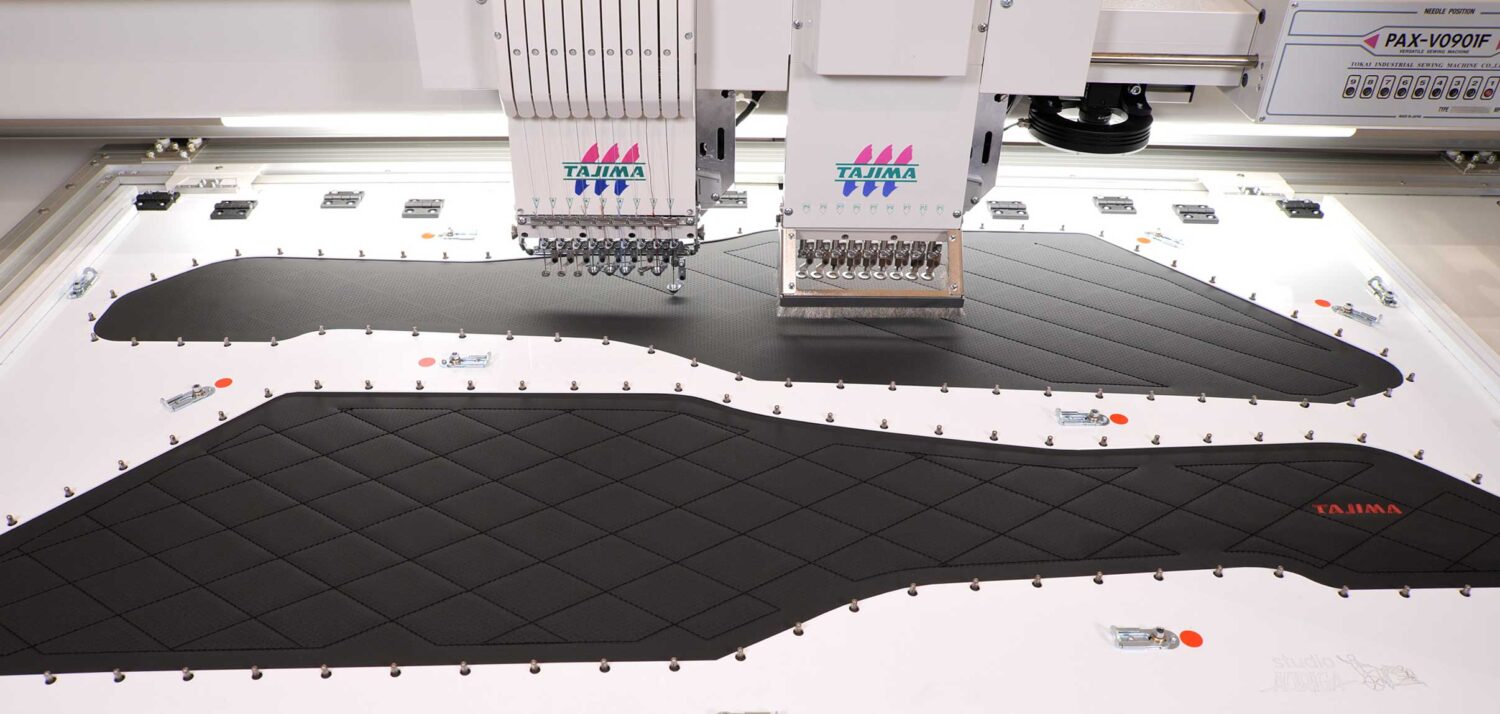

PAX enables sewing, embroidery, and perforation on various materials such as synthetic leather, vegan leather, and genuine leather, expanding possibilities not only functionally but also in terms of design. With this single machine, you can create new designs and beautiful finishes for interiors, furniture, leather goods, and other items to generate even greater appeal.

In addition, PAX has secured a wider sewable area than ordinary sewing machines by repurposing the high control technology it has accumulated over many years in embroidery machines.

It can handle a wide range of large items such as furniture.

Create beautiful embroidery on large items and delicate materials

Tajima’s embroidery machines can produce beautiful embroidery even on large items such as curtains, bedding, and furniture. By utilizing “Auto Frame Change (AFC),” embroidery can be efficiently applied to cloth such as curtains. In addition, using Tajima’s proprietary “i-TM” AI embroidery technology and “DCP” digitally controlled presser foot allows you to reproduce high-precision finishes, even on satin, silk, and other delicate materials—automatically.

From custom embroidery to artistic designs, Tajima’s total solutions add pizzazz to the interior industry.

Use personalization to create unique amenities

Amenities with initials, dates, or other custom details add a touch of luxury to daily life.

PulseID facilitates personalized embroidery tailored to the customer’s order.

TFP process combines design with the strength and durability of carbon fiber

Many industries in recent years have come to use carbon fiber, leveraging carbon’s properties of strength and lighter weight.

With the use of carbon fiber continuing to grow in the fields of aerospace, industry, sports, and other domains, the Tajima Group now offers process that maximize the properties of carbon fiber and further reduces the material’s weight and increases its rigidity.

Reinforced fibers have pronounced anisotropic characteristics, i.e., they provide strength only in the fiber’s orientation. This makes it difficult to use conventional process relying on unidirectional tape and sheets in reinforcing hollow, spiral, radial, and other such forms.

With Tajima’s TCWM Spec.2 fiber processing machine, a product of our embroidery technology, and the TFP (Tailored Fiber Placement) process developed through academic-industrial alliance, carbon fibers are repeatedly inserted in the areas of the base material where reinforcement is required, thus making possible to provide sufficient strength even for these previously difficult shapes. We support efforts to achieve carbon neutrality based on processing technology for reinforced fibers that are both light and strong.

Recommended Products

-

Multi-perfect sewing machine

PAX

Perforation, multicolor sewing, and embroidery, all in one machine. Suitable for leather processing.

-

-

Embroidery machine|Multi-head Flat Type

TMCR-VF+i-TM

Multi-head Flat Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Special machine

TCWM

Specialized composite fiber sewing machine for attaching reinforced fibers

-