Would you like to start personalizing embroidery?

These days, rather than simply purchasing products, today’s consumer tends to value unique, individualized items, so personalization businesses have become a new trend. This is accompanied by a simultaneous increase in demand for personalized embroidery, one way of creating totally unique items. However, there are issues that make it difficult to implement such services, with the complexity of running such an operation being one challenge.

Tajima utilizes cloud technology to simplify the more complicated aspects, increasing efficiency and supporting an environment that makes it easy to start personalizing embroidery.

Tajima’s unique cloud technology

enhances the efficiency of embroidery service operations

What is PulseID(DG.NET SaaS)?

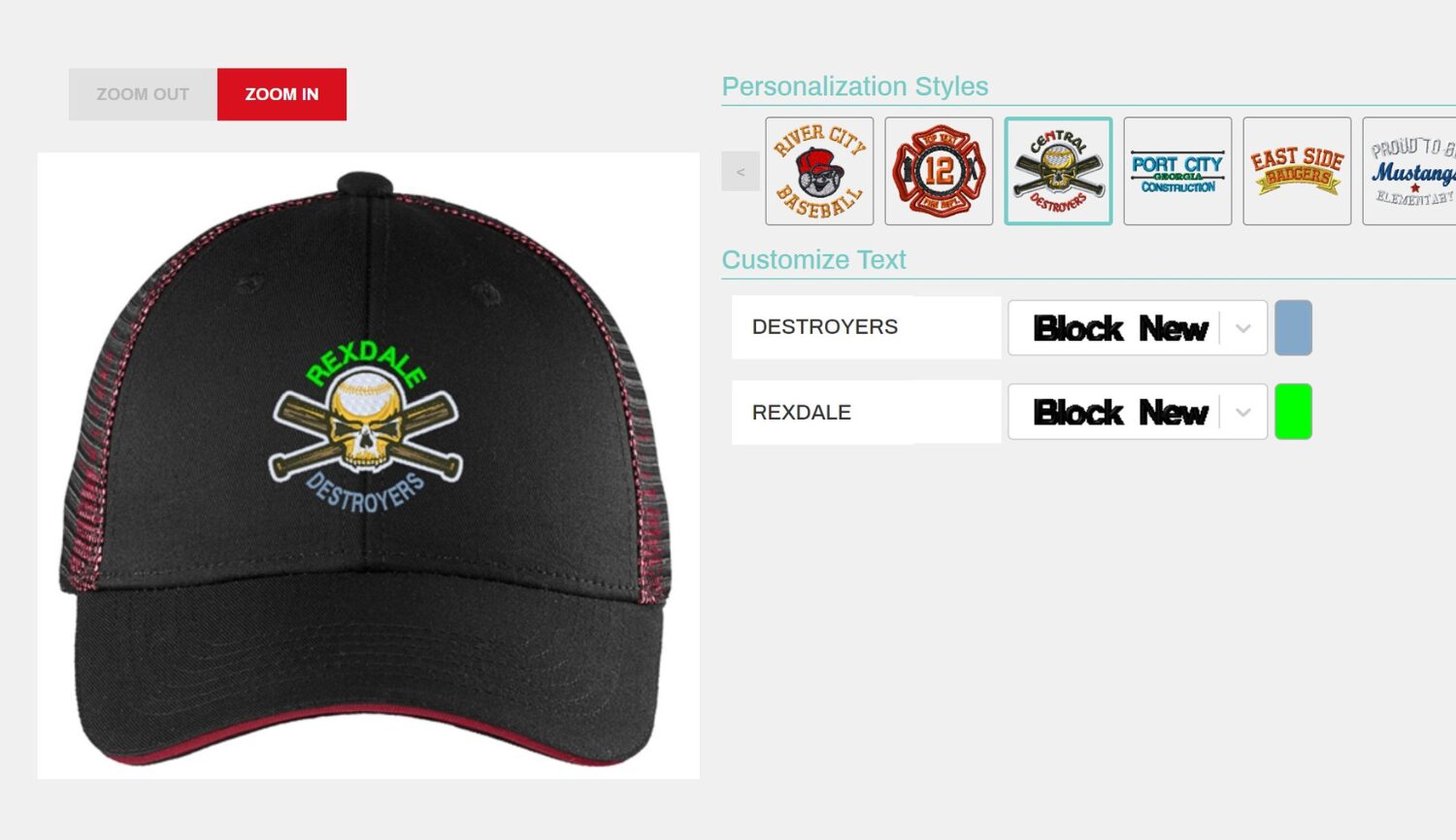

Offering flat-rate embroidery personalization on E-commerce site.

Embroiderers can easily receive and fill custom embroidery orders by linking with e-commerce platforms. This approach utilizes cloud technology, which holds down costs for development and other initial expenses, allowing businesses to introduce these services without any specialized programming knowledge.

Immediately fill e-commerce orders by contracting embroidery work to distribution sites.

Using PulseID, you can easily have embroidery added to your e-commerce orders just before they are shipped from the warehouse. This turns delivery centers into processing stations that create added value.

Advantages of implementing PulseID

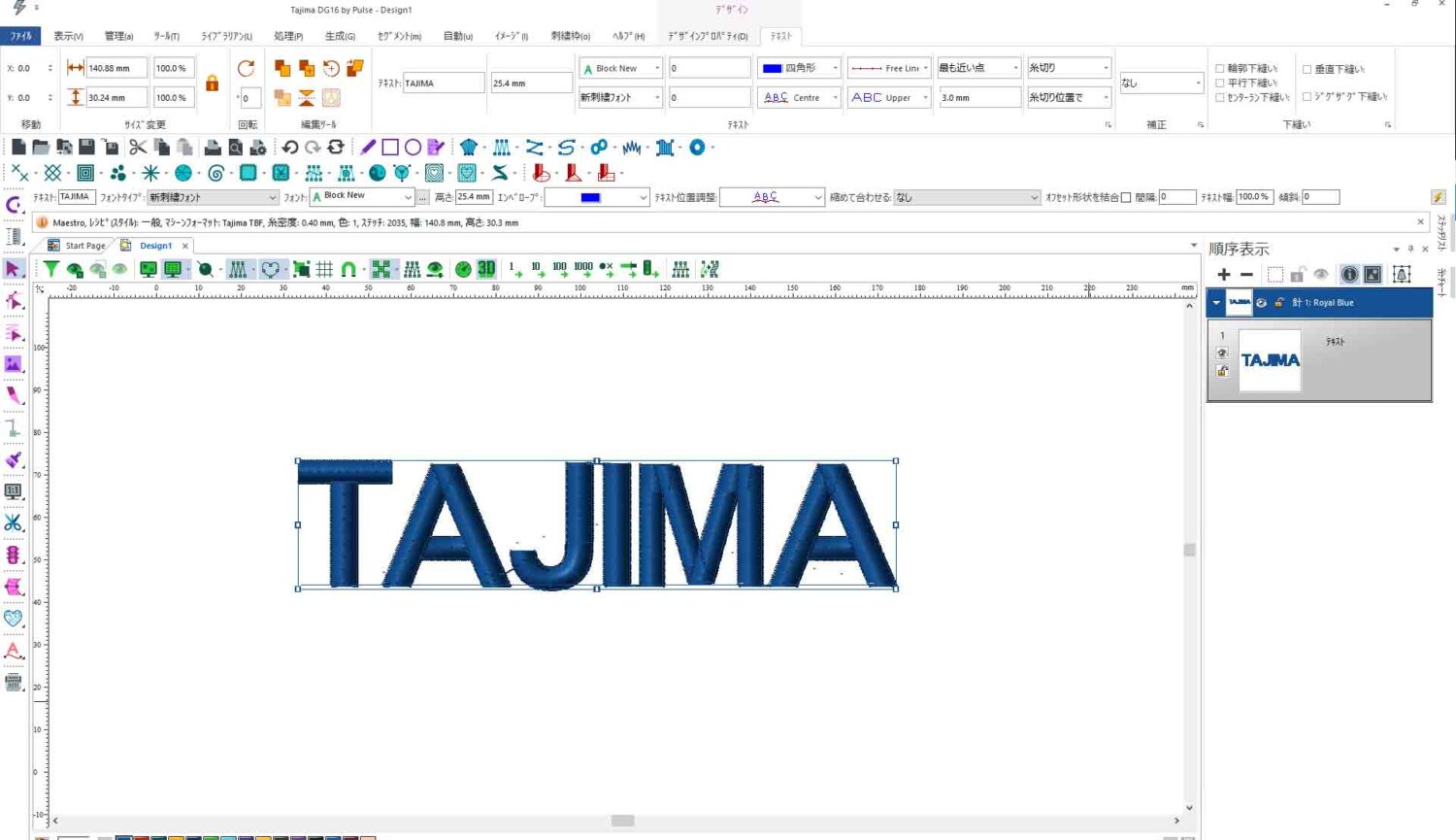

Automatically generates and previews embroidery data

Embroidery data on e-commerce sites is automatically generated and rendered as 3D previews. This prevents issues with the product differing from the customer’s vision. Another advantage is the enjoyment that customers derive in choosing the designs.

Embroidery data is immediately transferred to production

The accurately generated data is saved on the server along with thread color and other information, and the data then ready in standby. This greatly shortens the preparatory steps before production.

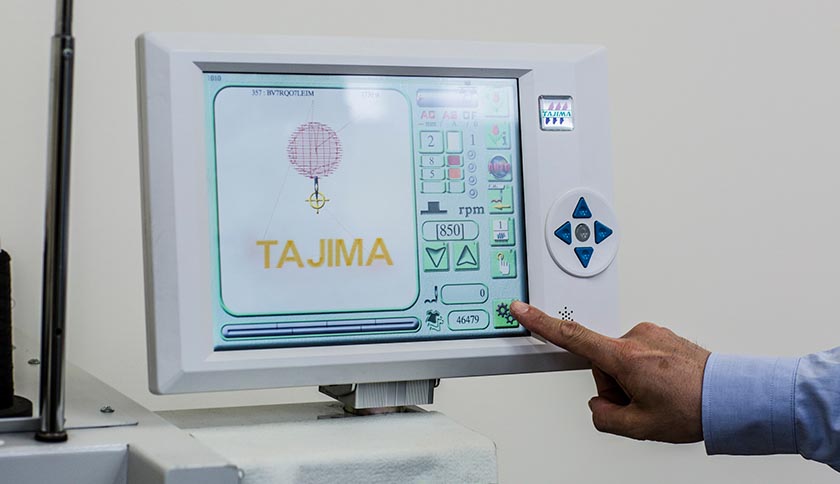

Data is transferred with barcodes

With a single scan, all of the data necessary for production is transferred to the embroidery machine. This reduces the steps of selecting the data and setting the machines while also preventing human errors such as mistakes in registration.

Post-implementation e-commerce sequence, from order to production

Ordering while viewing the preview on the e-commerce site

The user accesses the EC site and selects the embroidery. The user can also adjust the size and positioning while looking at the preview. The embroidery data is automatically generated when the order is made.

Users can operate the system and check the finished product themselves, which also results in an improved customer experience.

Data is transferred with barcodes

Embroidery data, thread color. and other instructional data are converted into a barcode and sent to the operator. When the barcode is read by the embroidery machine’s scanner, the data is then transferred to the embroidery machine.

Confirmation of the design

The data inputted into the embroidery machine is checked for any differences from the design.

Setting the frame / Embroidering

Once the setup is complete, the only thing necessary is to press the Start button. The TMEZ-SC can sew up to 1,000 stitches per minute, so an embroidery pattern of about ten characters can be completed in two to three minutes.

Beginners can create high-quality embroidery

with the “TMEZ-SC” AI embroidery machine.

It is said that operators need to be skilled in adjusting the upper thread, a major factor influencing the embroidery finish. With an embroidery machine equipped with Tajima’s “i-TM,” the AI can control the upper needle thread tension adjustment automatically. The system automatically programs the optimal settings in accordance with the thread type and fabric, so even inexperienced operators can easily create high-quality embroidery.

More about TMEZ-SC

For an entry model,

we recommend the compact “SAI” embroidery machine.

Demand for personalized embroidery is increasing not only with e-commerce, but also with in-person sales at brick-and-mortar shops.

The compact “SAI” embroidery machine is perfect for such in-store embroidery services.

Its compact design does not obstruct store space, and if placed and operated in a location visible from outside the store, its movement and distinctive sound will attract interest and draw in customers.

Recommended Products

-

Embroidery Software

PulseID(DG.NET SaaS)

System provides comprehensive support for the embroidery supply chain, from receipt of orders to production

-

-

Embroidery machine|Single-head Cylinder Type

TMEZ-SC

Single-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery machine|Single-head Cylinder Type

SAI

Tajima's compact machine, perfect for starting up an embroidery business and creating your own embroidery works!

- Entry

-

TAJIMAG

Case studies

-

Customer’s voice

Kutsushitaya Kichijoji store|Embroidery Services Fulfilling Customers’ Wishes Custom embroidery socks in just 30 minutes!

-

Customer’s voice

Tabio Nara Co., Ltd. | Introduction of the DG.NET embroidery solution creates new ways to enjoy embroidery!

-

Dialogue・Special feature

Tabio Co., Ltd. | Creating new value through embroidery. Producing one-of-a-kind socks, unique in all the world.